Outline of Thermal Power Generation

Role and Features

Role and Features

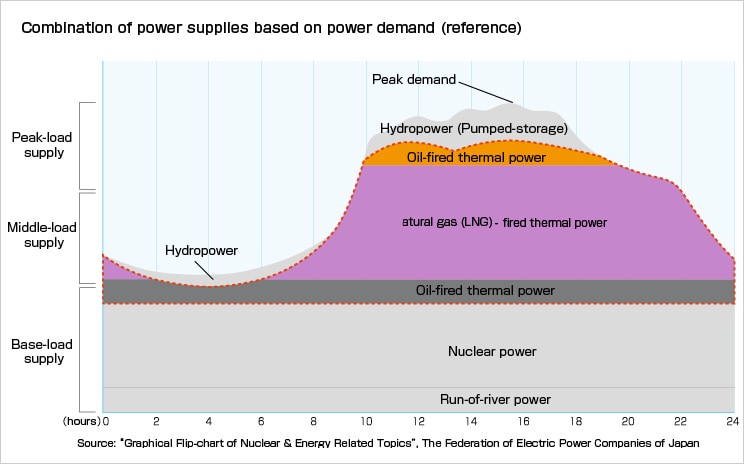

Electricity demand varies greatly by season and time of day. Because thermal power generation can flexibly adapt to changes in demand, it plays a central role in maintaining the power supply.

By combining various power sources, we can provide the quantity of power required to accommodate demand for the season and time of day.

| Type of power supply | Operational pattern | Features |

|---|---|---|

| Coal-fired thermal power | Base-load operation | Much like nuclear power, coal-fired thermal power is generated around-the-clock and the output is constant. It cannot be adjusted to respond to power demand fluctuations. |

| LNG-fired thermal power | Base-to-middle-load operation | These sources of power can be made to respond flexibly to daily fluctuations in electric power demand. They operate during the daytime, stop at night, and repeat this pattern daily. |

| Oil-fired thermal power | Middle-to-peak-load operation | These sources of power can be adjusted to accommodate peaks in electricity demand. They are operated mainly in summer and winter during periods of high demand. Otherwise they remain on standby and are ready to run at any time to provide reserve power when the demand spikes unexpectedly. |

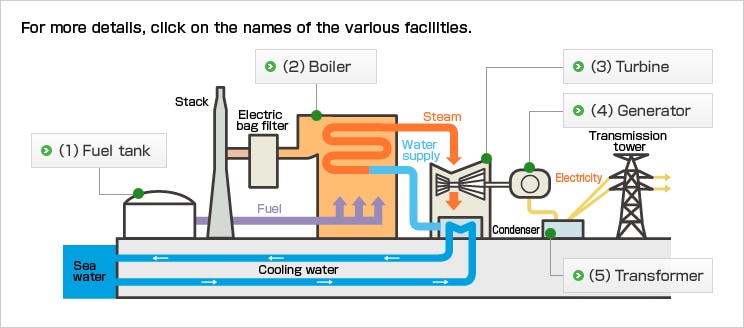

Basic Principle

Basic Principle

The burning of fuels such as oil, coal and LNG (liquefied natural gas) fires a boiler to generate high-temperature, high-pressure steam. This steam is used to drive a steam turbine. A generator attached to the steam turbine generates electricity.

Types of Thermal Power Generation

Types of Thermal Power Generation

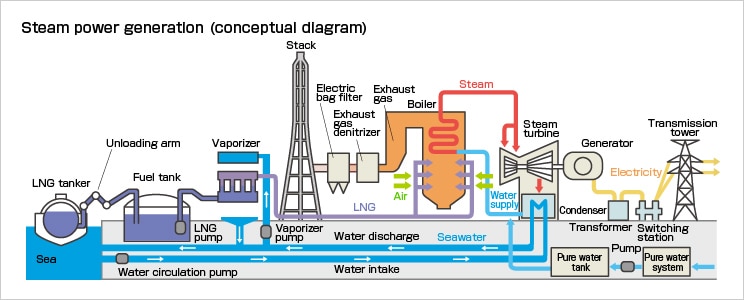

Steam power generation

Fuels such as heavy oil, LNG (liquefied natural gas) and coal are burned inside a boiler to generate steam at high temperature and high pressure.

This steam is used to rotate the impeller of the steam turbine. This drives the power generators connected to the turbine that generate electricity.

This system has a thermal efficiency of around 42% to 46% and functions as a base-to-middle-load supply.

Power stations utilizing steam power generation

- Nanko Power Station

- Maizuru Power Station

- Gobo Power Station

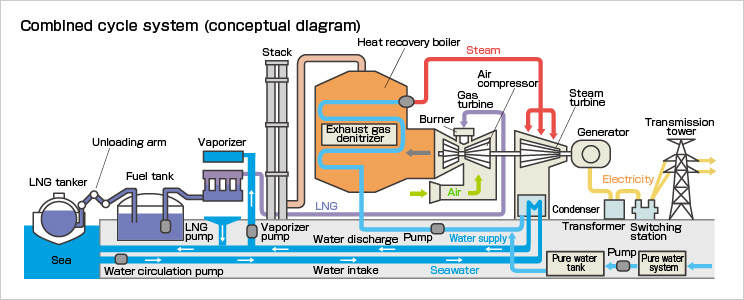

Combined cycle power generation

This method of generating electric power incorporates a gas turbine whose waste heat is reused to drive a steam turbine. The gas turbine is powered by high-temperature combustion gas that, after being discharged from the gas turbine, is efficiently recovered by means of a heat recovery boiler. This produces steam of sufficient temperature and pressure to drive the steam turbine and generate electricity. This configuration ensures high thermal efficiency, as the cost per unit of power generated is lower than that of oil-fired thermal power. It is used to provide the base-to-middle-load supply.

Power stations employing combined-cycle power generation

- Himeji No. 1 Power Station (Unit Nos. 5 & 6)

- Himeji No. 2 Power Station (Unit Nos. 1 ~ 6)

- Sakaiko Power Station

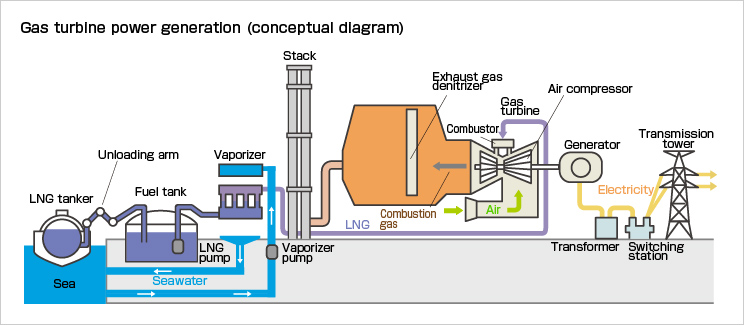

Gas turbine power generation

This electricity generating system makes electricity by burning fuels such as LNG (liquefied natural gas) or kerosene to produce high-temperature combustion gases with sufficient energy to rotate a gas turbine.

Power stations employing gas turbine power generation

- Himeji No. 1 Power Station (Unit Nos. 1 & 2)

- Kansai International Airport Energy Center