New Initiatives

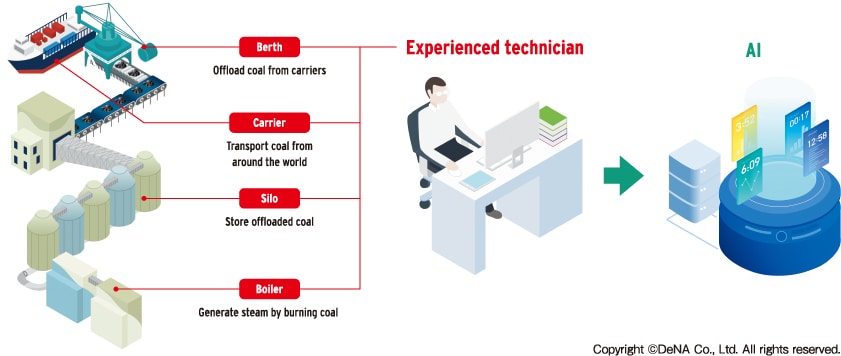

At coal-fired thermal power plants, coal is offloaded from carriers and temporarily stored in silos, after which it is burned in boilers. However, there are restrictions on what types of coal can be mixed and burned together, depending on the type of coal. For this reason, an experienced technician must create an operational schedule for multiple silos and boilers accommodating these restrictions based on years on experience and knowhow, and adjust operations to match the situation on the ground as necessary.

The goal of Kansai electric power and ALGO ARTIS* is to automate the fuel operation scheduling currently being handled by experienced technicians. Based on Kansai electric power’s particular challenges and operational conditions, ALGO ARTIS implemented technology that finds the optimal combination from among a massive number of possible combinations, which is often used in game AI, and built an algorithm.* *

As a result, we successfully developed a fuel operation optimization system that can automatically create longer schedules in less than one tenth of the time so far. This system is simple to use even by technicians with limited experience and is expected to be able to reduce the annual operating cost of tens of millions of yen by comparing the calculated schedules with multiple operational conditions at the same time.

The system has the potential to be used for scheduling in a variety of fields with processes ranging from receiving raw materials to product manufacturing, and thus is expected to provide to other companies.

*: ALGO ARTIS is the company that has the optimization solution business from independent from DeNA Co., Ltd.

* *:An algorithm refers to the specified order for solving a problem in fields such as mathematics and computing.